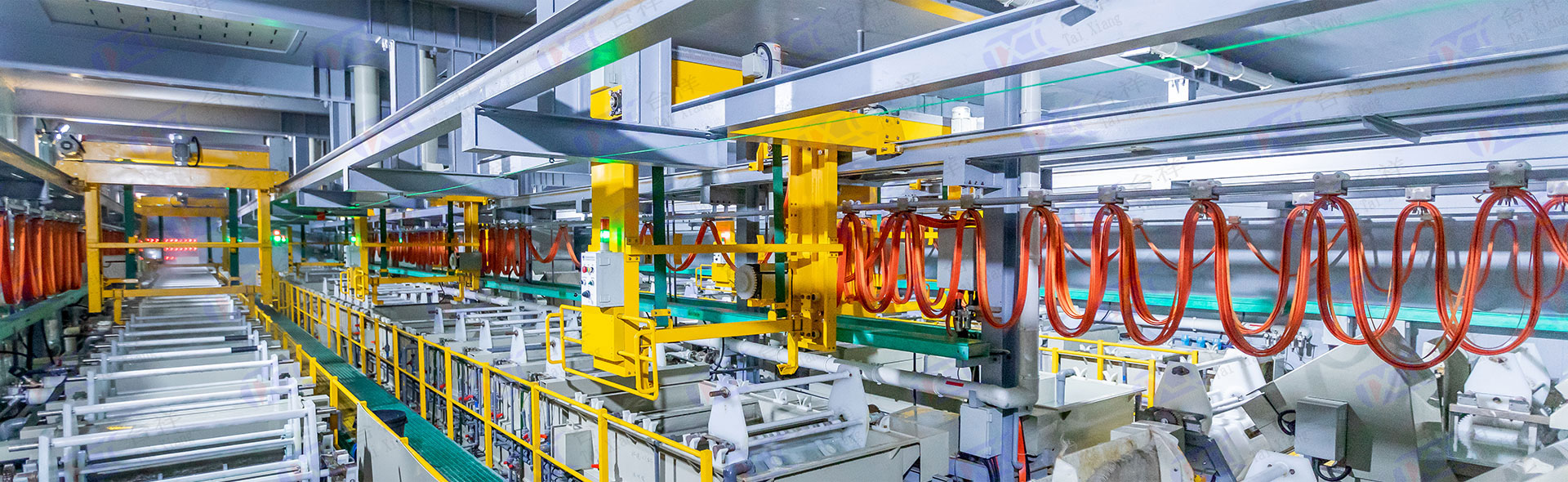

- The series of production lines can be fully automatic or semi-automatic converted, with a scientifically reasonable and compact design, and a high degree of automation;All affiliat...

Product details

The series of production lines can be fully automatic or semi-automatic converted, with a scientifically reasonable and compact design, and a high degree of automation;

All affiliated and peripheral devices related to this equipment are integrated into the main control panel for centralized management, facilitating operation and monitoring.

All components are made of well-known brand products with high circulation and good reputation to ensure high stability and high reliability of the equipment during long-term use.

Adopting a user-friendly control panel, in addition to achieving the goal of easy operation, it also has a high degree of error prevention and foolproof function. Incorrect operation and abnormalities will immediately alarm and stop working.

By monitoring the entire process through the human-machine interface, the cause of the fault can be queried for quick troubleshooting.

The plastic tank of this plating line is made of Germany Rochling or New PP material imported from Taiwan, which is durable . All Rinse tanks are equipped with collecting buckets that can facilitate the collection of pollutants and achieve low level drainage, so the bottom of tanks can be cleaned up. There are water baffles between tanks to prevent splashing or dripping liquid from seeping into the gaps and forming ponding.

Frame: The overall structure is a low rail structure, supported by stainless steel anchor bolts, without the need for pre-buried. All tanks are placed on the platform of the frame and drip trays are made under the tanks and on the ground. The frame installation uses a level tester to adjust which can improve installation accuracy and ensure smooth driving for hoist. After surface shot blasting, use rainbow brand epoxy resin paint for anti-corrosion.

The rotary roller can be drilled using modular, mesh mode, and conventional PP materials according to customer’s requirement; The rotary roller has good conductivity, flexible transmission, and no jitter.

The work pedal and foot rest are all made of SUS304 material, and laid with high-strength acid and alkali resistant FRP grating plates.

The plating line adopts a scientific and environmentally designing to improve the working environment and prolong the service life of the plating line.

All circuits and pipelines of this plating line have been carefully considered, which not only facilitates user operation, but also provides simplicity and efficiency in the use and maintenance of various circuits and fittings.

The plating line is widely used in hardware, electronics, automobiles, lighting furniture and other industries.

- Previous: Intelligent hoist type rolling plating line

- Next: Last Already